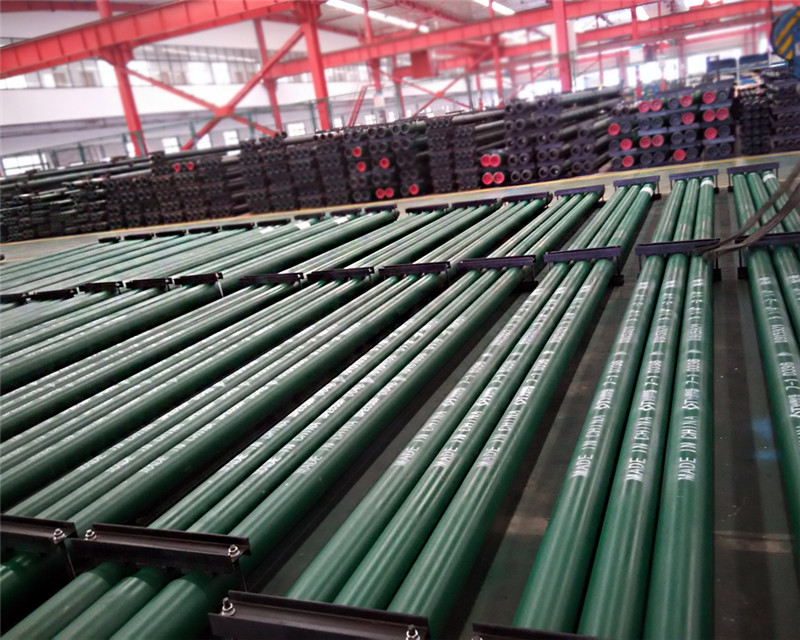

Iimveliso

API 7-1 4145&Non-mag Drill Collar

Ingcaciso yeMveliso

Ikhola yoqheliso eqhelekileyo licandelo lomnqamlezo ojikelezayo, iziko linomngxuma wamanzi, ubukhulu bodonga bukhulu, umlomo wombhobho umncinci, ubunzima bobude beyunithi nganye bukhulu kunobukhulu bombhobho wokubhola phantse amaxesha ama-4-5. i-drill collar is thread processing ngqo kumzimba wombhobho , kodwa ezinye zazo zisebenzisa indawo edibeneyo.

Ikhola ye-Spiral drill luhlobo lwesixhobo sokugaya i-petroleum .Olu hlobo lwekhola ye-drill luyakwazi ukuthintela ukugcinwa koxinzelelo oluhlukeneyo lwezixhobo ngexesha lokugaya. I-Spiral grooves iyakwenza ukuba udaka luhambe ngokukhululekileyo lujikeleze ikhola ye-drill ukusebenzisa uxinzelelo olulinganayo ukuthintela ukwakheka kwesithintelo ukuze kuthintelwe ngokufanelekileyo ukuxinana koxinzelelo oluhlukeneyo. Indawo yokudibanisa eludongeni lwequla inokunqunyulwa ukuze kuncitshiswe ngokufanelekileyo ukuba nokwenzeka kokwenza umqobo wokudityaniswa koxinzelelo. I-Spiral grooves iyakwenza ukuba udaka luhambe ngokukhululekileyo lujikeleze ikhola ye-drill ukusebenzisa uxinzelelo olulinganayo ukuthintela ukwakheka kwesithintelo ukuze kuthintelwe ngokufanelekileyo ukuxinana koxinzelelo oluhlukeneyo. Indawo yokudibanisa eludongeni lomthombo inokunqunyulwa ukuze kuncitshiswe ngokufanelekileyo ithuba lokudala umqobo wokudityaniswa koxinzelelo. Ubunzima bekhola ye-spiral drill yi-4-6% ngaphantsi kobo bekhola yokubhola engqukuva.

Ikhola yokuDrila engeyiyo iMagnetic: Iikhola ze-non-magnetic Drill zenziwe ngezinto zekhola zokuqhuba i-Non-magnetic drill ezinamandla aphantsi ngokudibanisa uhlalutyo lweekhemikhali zobunikazi kunye nenkqubo yokujikeleza kwesando esijikelezayo esinezibuthe ezisezantsi ezinobunewunewu obugqwesileyo bomatshini. sinokubonelela ngobude ukusuka kwi-10 ukuya kwi-42 kwaye ngaphandle kwedayamitha ukusuka kwi-31/8" ukuya kwi-11'.

Ukucaciswa kweMveliso

| Ubungakanani | OD(mm) | Isazisi(mm) | Ikhowudi | Umsonto | Ubude(mm) | Ubunzima(kg) |

| 3-1/8 | 79.4 | 31.8(1-1/4) | NC23-31 | NC23 | 9140 | 298 |

| 3-1/2 | 88.9 | 38.1(1-1/2) | NC26-35 | NC26 | 9140 | 364 |

| 4-1/8 | 104.8 | 50.8(2) | NC31-41 | NC31 | 9140/9450 | 474/490 |

| 4-3/4 | 120.6 | 50.8(2) | NC35-47 | NC35 | 9140/9450 | 674/697 |

| 5 | 127 | 57.2(2-1/4) | NC38-50 | NC38 | 9140/9450 | 725/749 |

| 6 | 152.4 | 57.2(2-1/4) | NC44-60 | NC44 | 9140/9450 | 1125/1163 |

| 71.4(2-13/16) | NC44-60 | 9140/9450 | 1022/1056 | |||

| 6-1/4 | 158.8 | 57.2(2-1/4) | I-NC44-62 | NC44 | 9140/9450 | 1237/1279 |

| 71.4(2-13/16) | I-NC46-62 | 9140/9450 | 1134/1172 | |||

| 6-1/2 | 165.1 | 57.2(2-1/4) | I-NC46-65 | NC46 | 9140/9450 | 1352/1398 |

| 71.4(2-13/16) | I-NC46-65 | NC50 | 9140/9450 | 1249/1291 | ||

| 6-3/4 | 171.4 | 57.2(2-1/4) | I-NC46-67 | NC46 | 9140/9450 | 1471/1521 |

| 7 | 177.8 | 57.2(2-1/4) | NC50-70 | NC50 | 9140/9450 | 1597/1651 |

| 71.4(2-13/16) | NC50-70 | 9140/9450 | 1494/1545 | |||

| 7-1/4 | 184.2 | 71.4(2-13/16) | NC50-72 | NC50 | 9140/9450 | 1625/1680 |

| 7-3/4 | 196.8 | 71.4(2-13/16) | NC56-77 | NC56 | 9140/9450 | 1895/1960 |

| 8 | 203.2 | 71.4(2-13/16) | NC56-80 | NC56/6-5/8REG | 9140/9450 | 2040/2109 |

| 8-1/4 | 209.6 | 71.4(2-13/16) | 6-5/8REG | 6-5/8REG | 9140/9450 | 2188/2263 |

| 9 | 228.6 | 71.4(2-13/16) | NC61-90 | NC61 | 9140/9450 | 2658/2748 |

| 9-1/2 | 241.3 | 76.2(2-13/16) | 7-5/8REG | 7-5/8REG | 9140/9450 | 2954/3054 |

| 9-3/4 | 247.6 | 76.2(3) | NC70-97 | NC70 | 9140/9450 | 3127/3234 |

| 10 | 254 | 76.2(3) | NC70-100 | NC70 | 9140/9450 | 3308/3421 |

| 11 | 279.4 | 76.2(3) | 8-5/8REG | 8-5/8REG | 9140/9450 | 4072/4210 |

Iimpawu kunye neeNzuzo

Uluhlu lobunzima be-285 ukuya kwi-341 BHN kunye nexabiso lempembelelo ye-Charpy ye-40 ft-lbs iqinisekisiwe ngokusasazwa ngokulinganayo amanqaku e-16 kuwo nawaphi na amacandelo anqamlezayo kwiqondo lokushisa;

Uqhagamshelo luqatywe iphosphate emva komatshini ukukhusela imisonto kwizinto ezidliwayo kunye nokuthintela ukurhabaxa xa kusenziwa okokuqala;

Iingcambu zomsonto ziqengqiwe ngokubanda kuqhagamshelo lwe-API;

Izikhuseli zentsimbi ezicinezelweyo zibonelelwa kuzo zonke iikhola zokuqhuba ezixhotyiswe ngokudityaniswa okusemgangathweni.

Iinketho

Umjelo wokunceda uxinzelelo. Iimpawu zokunciphisa uxinzelelo kwipini ye-API kunye noqhagamshelo lwebhokisi ukunciphisa uxinzelelo oluphezulu ngaloo ndlela kuphuculwe amandla okugoba malunga neendawo zonxibelelwano.

Ukuqengqeleka okubandayo kweengcambu zentambo kubonise iziphumo eziluncedo zokuphucula ukudinwa koqhagamshelo ngokunciphisa ukuqaliswa kokuqhekeka.

Hardbanding. Ukudityaniswa kwentsimbi kwiindawo ezingaphantsi nangaphezulu kwekhefu lokutyibilika okanye kwigxalaba lentsimbi kwandisa ubomi benkonzo yeekhola zokomba. Inokusetyenziswa kwakhona kuqwalaselo oluchazwe ngabathengi. Ukudityaniswa kwentsimbi kwiindawo ezingaphantsi nangaphezulu kwekhefu lokutyibilika okanye kwigxalaba lentsimbi kwandisa ubomi benkonzo yeekhola zokomba. Inokusetyenziswa kwakhona kuqwalaselo oluchazwe ngabathengi.

Ukutyibilika kunye neendawo zokuhlala kwi-elevator. Iradiyasi ephezulu yekhefu ye-elevator iyaqengqeleka ukuze kuphuculwe ubomi bemveliso. I-Slip kunye ne-elevator recesses zenziwe ngokuhambelana ne-API Spec 7-1.

Igumbi 703 Isakhiwo B, iziko Greenland, Hi-tech uphuhliso zone Xi'an, China

Igumbi 703 Isakhiwo B, iziko Greenland, Hi-tech uphuhliso zone Xi'an, China 86-13609153141

86-13609153141