Iimveliso

Ukusebenza okuphezulu kwe-Downhole Milling Tools

IMveliso yeMveliso

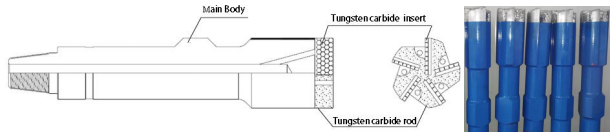

Thatha izihlangu ezisicaba ezisezantsi njengomzekelo:

Umzimba oyintloko uthatha i-high-performance alloy steel (4145H) ukuqinisekisa ukusebenza kakuhle kunye nokusebenza kakuhle phantsi koxinzelelo oluhlukeneyo lokugaya kunye nesantya esijikelezayo. Ngeli xesha, sisebenzisa inqanaba eliphezulu le-tungsten carbide imitha yokufezekisa ukugaya ngokukhawuleza. I-stabilizer kunye ne-skirt yangaphandle ye-junk mill kunye ne-taper mill inokuyilwa njengemfuneko.

Faka i-tungsten carbide

·Umgangatho ophezulu

Ukuzalisa okulungileyo kwi-watermelon, intambo kunye ne-taper mills.

Ubuyile kakuhle kwizingqusho ezingafunekiyo.

Uluhlu olubanzi lweesayizi ezikhoyo.

Uninzi olunzima.

· Metal Muncher

IiMill ngokukhawuleza kunezixhobo zokugaya eziqhelekileyo.

Yehlisa uxinzelelo olufunekayo lokomba ngelixa lokusila.

Ishiya imisimbo egudileyo engenamlomo ukwenzela ukuba inkunkuma ijinga.

Ivelisa inkunkuma enobungakanani obufanayo.

Ukusika isinyithi endaweni yokusila.

· I-Opti-cut

Inkunkuma encinci.

I-ROP ekhawulezayo.

Ubomi obude.

Uxinzelelo oluphantsi kunye neemfuno zetorque.

Amanqaku ayi-16 okusika kunye neengcambu ezi-8 zokusika kwi-cutter nganye.

Udidi lweMveliso

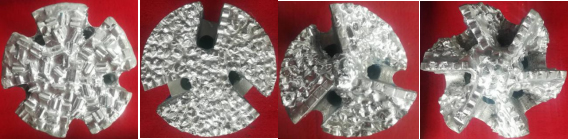

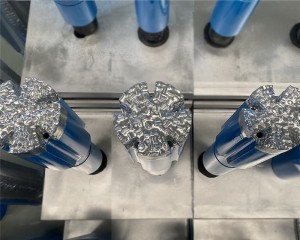

Concave/Flat/Blade Bottom junk mill

Isetyenziselwa ukungqusha, ikhowuni, igeyiji yobubanzi, amazinyo okubamba, umbhobho wokuhlamba, isixhobo sokomba esidityanisiweyo, izincedisi zempompo yequla elinzulu, ipaki, umsasazi wamanzi kunye nezinye izixhobo zokomba ezinde.

I-Petrozhr junk mill ifumaneka kwiimpawu ezahlukeneyo kunye neejometri. Ubunjineli bethu bokusila obuphambili kunye ne-welder enamava iqinisekisa ubume obungaguqukiyo kunye nesigxina sokusika kuyo yonke i-junk mill.

Ithebhu. 1 I-Flat/Concave/Blade Bottom junk mill parameter

| IBorehole Dia. Mill Shoe OD Kucetyiswa Ubude (mm) (mm) Umsonto wokuScrew (mm) | PN Umcaba | PN Concave | PN Ifakwe intsimbi |

| 95.2- 101.6 89 2-3/8REG 250 | JM089FX | JM089CX | JM089BX |

| 107.9- 114.3 97 2-3/8REG 250 | JM097FX | JM097CX | JM097BX |

| 117.5- 127 110 2-7/8REG 250 | IJM110FX | I-JM110CX | IJM110BX |

| 130- 139.7 121 2-7/8REG 250 | IJM121FX | IJM121CX | IJM121BX |

| 142.9- 152.4 130 2-7/8REG 250 | IJM130FX | I-JM130CX | IJM130BX |

| 155.6- 165. 1 140 3- 1/2REG 250 | IJM140FX | I-JM140CX | IJM140BX |

| 168- 187.3 156 3- 1/2REG 250 | IJM156FX | IJM156CX | IJM156BX |

| 190.5-209.5 178 3- 1/2REG 250 | IJM178FX | IJM178CX | JM178BX |

| 212.7-241.3 200 4- 1/2REG 250 | JM200FX | JM200CX | JM200BX |

| 244.5-269.9 232 4- 1/2REG 250 | JM232FX | JM232CX | JM232BX |

| 273-295.3 257 6-5/8REG 250 | JM257FX | JM257CX | JM257BX |

| 298.5-317.5 279 6-5/8REG 250 | JM279FX | JM279CX | JM279BX |

| 320.6-346. 1 295 6-5/8REG 250 | JM295FX | JM295CX | JM295BX |

| 349.3-406.4 330 6-5/8REG 250 | JM330FX | JM330CX | JM330BX |

| 406.4-444.5 381 6-5/8REG 250 | JM381FX | JM381CX | JM381BX |

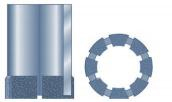

I-Rotary Shoe

Isihlangu esijikelezayo sithatha izinto ze-carbide ngaphakathi kwe-cylinder ukuze zinqumle ngokujikelezayo intlanzi ephezulu, kwaye ngokuthe ngcembe ilungise umphezulu wentlanzi eyonakeleyo kwisangqa, njenge-tubing, i-casing body, njl.

[Qaphela: Ngenxa yokuba i-diameter yangaphakathi yamazinyo yokusila yesihlangu esijikelezayo sikhulu, i-torque ejikelezayo inkulu, ngoko ke uxinzelelo oluphantsi kunye nemowudi yokujikeleza ngokukhawuleza kufuneka yamkelwe ekusebenziseni isihlangu esijikelezayo. Ngokubanzi, uxinzelelo lokugaya akufanele ludlule i-10 KN kwaye isantya sokujikeleza akufanele sidlule i-50 r / min.]

Uhlobo A

Sika isinyithi, isamente kunye nokwakheka.

Ukusika kwi-OD kunye nezantsi.

Uhlobo B

Ukusika isinyithi apho imvume incinci.

Ukusika kwi-ID kunye nezantsi.

Uhlobo C

Sika ukubunjwa.

Ukusika kwi-OD kunye nezantsi.

Uhlobo D

Sika ukubunjwa kunye neentlanzi ngexesha elifanayo.

Ukusika kwi-ID, i-OD kunye nezantsi.

Ithebhu.2 Ipharamitha yesihlangu esijikelezayo

| Casing / Wellbore Dia. | I-Rotary shoe OD (mm) | Isihlangu esijikelezayo Ubude (mm) | Kucetyiswa iScrew Thread | PN I-Rotary Shoe | |

| 4in | 101.6mm | 95 400 | FJWP | TXX095 | |

| 5- 1/2in | 139.7mm | 114 500 | FJWP | TXX114 | |

| 5-3/8in | 146.05mm | 118 500 | FJWP | TXX118 | |

| 6-5/8in | 168.28mm | 136 425 | FJWP | TXX135 | |

| 7in | 177.8mm | 152 450 | FJWP | TXX152 | |

| 7-5/8in | 193.68mm | 160 450 | FJWP | TXX160 | |

| 8-5/8in | 219. 1mm | 185 550 | FJWP | TXX185 | |

| 12- 1/4in 311. 15mm | 203 450 | FJWP | TXX203 | ||

| 15-5/8in 396.88mm | 298 450 | FJWP | TXX298 | ||

| 20in | 508mm | 406 450 | FJWP | TXX406 | |

Taper Mill

Ilitye lokusila letaper likhupha izithintelo, icasing edilikileyo kunye namacandelo e-liner kunye ne-deburr whipstock windows kunye ne-casing. Isiphelo esisezantsi se-taper mill, kunye nencinci, idiameter ingena kwi-casing edilikileyo kunye ne-liner. Idayamitha yokusila.

I-taper mill iquka umzimba we-conical kunye ne-tungsten carbide. I-taper yomzimba i-degrees ezingama-30, i-cone ifana nephiko, kwaye umphezulu unzima okanye u-inlaying tungsten carbide.

Tab.3 iparamitha yokugaya iTaper

| Umngxuma wamanzi Dia. Taper ilitye lokusila OD Iyacetyiswa Ubude (mm) (mm)Screw Umsonto(mm) | P.N. Taper ilitye lokusila | ||

| 95- 101.6 | 89 | 2-3/8REG 300 | XZ089 |

| 107.9- 114.3 97 2-3/8REG 300 | XZ097 | ||

| 117.5- 127.0 110 2-7/8REG 300 | XZ110 | ||

| 130- 139.7 121 2-7/8REG 300 | XZ121 | ||

| 142.9- 152.4 130 2-7/8REG 300 | XZ130 | ||

| 155.6- 165. 1 140 3- 1/2REG 300 | XZ140 | ||

| 168- 187.3 156 3- 1/2REG 300 | XZ156 | ||

| 190.5-209.5 178 3- 1/2REG 300 | XZ178 | ||

| 212.7-241.3 200 4- 1/2REG 300 | XZ200 | ||

| 244.5-269.9 232 6-5/8REG 350 | XZ232 | ||

| 273-295.3 257 6-5/8REG 350 | XZ257 | ||

| 298.5-317.5 279 6-5/8REG 350 | XZ279 | ||

| 320.6-346. 1 295 6-5/8REG 350 | XZ295 | ||

| 349.3-406.4 330 6-5/8REG 350 | XZ330 | ||

| 406.4-444.5 381 6-5/8REG 350 | XZ381 | ||

IWatermelon String Mill

Isihlangu somtya we-Watermelon sesinye sezixhobo zokusila kwindlela yokusebenza esecaleni. Isetyenziselwa ukulungisa i-casing, i-reaming kunye nokuvula amajelo. Ngokuqhelekileyo isetyenziswe ngokukhawuleza emva kokuvula iifestile. Umgca wokusila (indawo yokusebenza) ye-watermelon mill idibanisa nodonga lwe-borehole, kwaye isiphelo somphetho ngamnye siyilwe njenge-cone. Xa ifestile ivulwa, i-watermelon mill inokwandisa ifestile ukusuka phezulu kwaye isuse i-scaling kunye ne-burrs eshiywe eludongeni lombhobho ngexesha lokusika kokuqala.

I-Tab.4 ipharamitha ye-Watermelon yokusila

| IBorehole Dia. Screw (mm/in ) Umsonto | Indawo yokusebenzela OD (mm/ngaphakathi) | Ubude beNdawo yokuSebenza (mm/in) | Ubude obupheleleyo (mm/ngaphakathi) | PN |

| 139.7 (5- 1/2) NC 26 112 (4-7/ 16) 600 (23-5/8) | 1130 (44) | XGMX112 | ||

| 139.7 (5- 1/2) NC 26 116 (4-9/ 16) 600 (23-5/8) | 1130 (44) | XGMX116 | ||

| 139.7 (5- 1/2) NC 26 118 (4-5/8) 600 (23-5/8) | 1130 (44) | XGMX118 | ||

| 139.7 (5- 1/2) NC 31 120 (4-3/4) 600 (23-5/8) | 1280 (50) | XGMX120 | ||

| 146.0 (5-3/4) NC 31 124 (4-7/8) 600 (23-5/8) | 1280 (50) | XGMX124 | ||

| 168.3 (6-5/8) NC 31 142 (5-9/ 16) 600 (23-5/8) | 1280 (50) | XGMX142 | ||

| 177.8 (7) NC 31 151 (5- 15/ 16) 600 (23-5/8) | 1280 (50) | XGMX151 | ||

Ilitye lokusila

Ilitye lokusila lenzelwe ukungqusha, iliner, isihlangu esijikelezayo okanye iityhubhu enkulu ye-ID. Amacwecwe okusika agqoke ngeeklasi eziphezulu ze-tungsten carbide izinto zenza i-Petrozhr pilot mill inokufikelela ukungena ngokukhawuleza kunye nokugqoka okuncinci.I-debris yokusika encinci kunye ne-curled kulula ukuyisusa. Kwaye isiphelo sokulinga sisetyenziselwa ukuzinzisa kwi-ID yento egayiweyo.

I-Tab.5 Ipharamitha ye-Pilot mill

| Umngxuma wamanzi Dia. (mm) | Screw Umsonto | Indawo yokusebenzela OD (mm) | Incakuba yokusika Ubude (mm) | Indawo yokulinga Ubude (mm) | PN |

| 153 2 3/8REG | 130 200 | ≧45 | I-LYMX130 | ||

| 165 2 3/8REG | 140 200 | ≧45 | I-LYMX140 | ||

| 187 3 1/2REG | 156 200 | ≧55 | I-LYMX156 | ||

| 210 4 1/2REG | 178 200 | ≧55 | I-LYMX178 | ||

| 241 4 1/2REG | 200 200 | ≧55 | I-LYMX200 | ||

| 270 4 1/2REG | 232 200 | ≧55 | I-LYMX232 | ||

| 295 6 5/8REG | 257 250 | ≧55 | I-LYMX257 | ||

| 317 6 5/8REG | 279 250 | ≧55 | I-LYMX279 | ||

| 346 6 5/8REG | 295 300 | ≧55 | I-LYMX295 | ||

| 406 6 5/8REG | 330 300 | ≧55 | I-LYMX330 | ||

| 445 6 5/8REG | 331 300 | ≧55 | I-LYMX331 | ||

Itshathi yesicelo seTungsten carbide

| Isicelo esicetyiswayo | Superloy | I-Opti-cut | Metal-muncher | Metal-muncher kunye neSuperloy |

| Washover umngxuma ovulekileyo | √ | √ | ||

| Umbhobho we-washover drill | √ | |||

| Washover gravel pack | √ | √ | ||

| I-washover liner trim | √ | |||

| Washover packer | √ | |||

| Ukusila ipoyile | √ | |||

| Ukuguba iJunk milling | √ | √ | ||

| Umpakishi omileyo okanye umbhobho okanye i-tubingjunk milling | √ | |||

| Ukugaya ivatala | √ | |||

| Ukugaya umtya | √ |

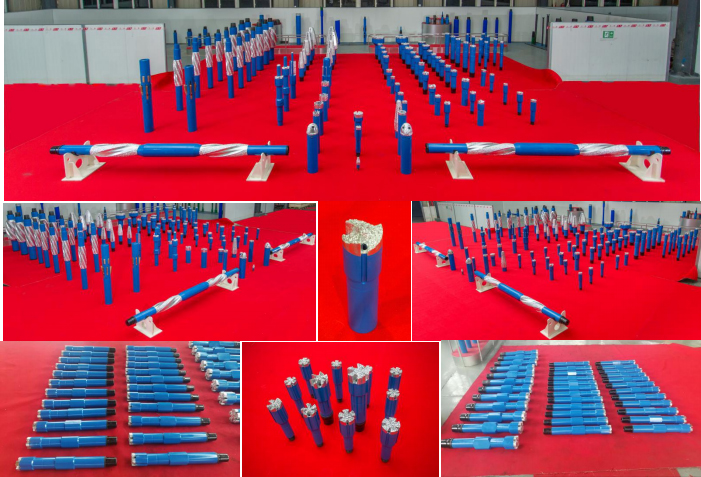

Imifanekiso yento yokuloba

Igumbi 703 Isakhiwo B, iziko Greenland, Hi-tech uphuhliso zone Xi'an, China

Igumbi 703 Isakhiwo B, iziko Greenland, Hi-tech uphuhliso zone Xi'an, China 86-13609153141

86-13609153141