Iimveliso

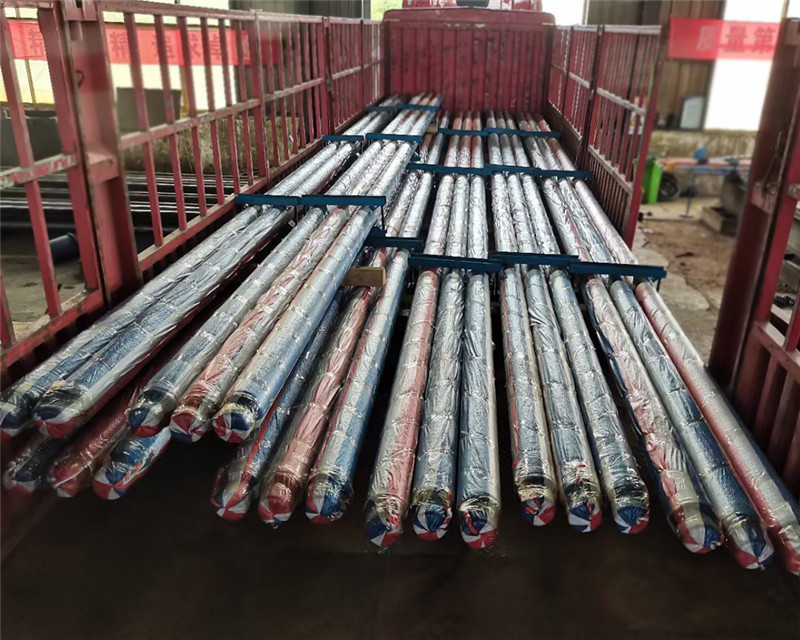

Non-Magnetic Drill Collars & subs

IKhola yokuDla i-Non-Magnetic

IKhola yokuDrila eSlick engeyiyo-Mag

Ikhola ye-Slick ye-Non-Mag Drill ibonelela ngobunzima obufunekayo kwi-bit, kwaye ayiyi kuphazamisa isakhono sokuqondisa.

Spiral Non-Mag Drill Ikhola

I-Spiral Non-Mag Drill Collar yenzelwe ukuvumela indawo ehambayo enkulu yokucoca ulwelo, ngelixa ibonelela ngeenzuzo zentsimbi engeyiyo-mag kwiinkqubo zokomba ezintsonkothileyo.

Flex Non-Mag Drill Ikhola

I-Flex Non-Mag Drill Collar ibhityile kwaye ibhetyebhetye ngakumbi kunekhola yedrill eqhelekileyo. Ukukwazi kwabo ukwenza ujiko olufutshane lweradiyasi, ukugoba ii-engile zokwakha eziphezulu, kunye nokudlula kwii-doglegs ezibukhali kubenza balungele ukusetyenziswa kwizicelo ezithe tyaba kunye nezithe tye. Yenziwe ngentsimbi engeyiyo imag, le khola ye-drill ifaneleka kakuhle kwizixhobo ze-MWD zezindlu.

Ukucaciswa kweMveliso

| Uqhagamshelwano | OD mm | ID mm | Ubude mm |

| NC23-31 | 79.4 | 31.8 | 9150 |

| NC26-35 | 88.9 | 38.1 | 9150 |

| NC31-41 | 104.8 | 50.8 | 9150 okanye 9450 |

| NC35-47 | 120.7 | 50.8 | 915 okanye 9450 |

| NC38-50 | 127.0 | 57.2 | 9150 okanye 9450 |

| NC44-60 | 152.4 | 57.2 | 9150 okanye 9450 |

| NC44-60 | 152.4 | 71.4 | 9150 okanye 9450 |

| I-NC44-62 | 158.8 | 57.2 | 9150 okanye 9450 |

| I-NC46-62 | 158.8 | 71.4 | 9150 okanye 9450 |

| I-NC46-65 | 165.1 | 57.2 | 9150 okanye 9450 |

| I-NC46-65 | 165.1 | 71.4 | 9150 okanye 9450 |

| I-NC46-67 | 171.4 | 57.2 | 9150 okanye 9450 |

| NC50-67 | 171.4 | 71.4 | 9150 okanye 9450 |

| NC50-70 | 177.8 | 57.2 | 9150 okanye 9450 |

| NC50-70 | 177.8 | 71.4 | 9150 okanye 9450 |

| NC50-72 | 184.2 | 71.4 | 9150 okanye 9450 |

| NC56-77 | 196.8 | 71.4 | 9150 okanye 9450 |

| NC56-80 | 203.2 | 71.4 | 9150 okanye 9450 |

| 6 5/8REG | 209.6 | 71.4 | 9150 okanye 9450 |

| NC61-90 | 228.6 | 71.4 | 9150 okanye 9450 |

| 7 5/8REG | 241.3 | 76.2 | 9150 okanye 9450 |

| NC70-97 | 247.6 | 76.2 | 9150 okanye 9450 |

| NC70-100 | 254.0 | 76.2 | 9150 okanye 9450 |

| 8 5/8REG | 279.4 | 76.2 | 9150 okanye 9450 |

Uzinzisi weMagnetic

I-integral non magnetic stabilizer yenziwe ngentsimbi enye eqinileyo. Izinto eziphathekayo bubunyulu obuphezulu beChromium Manganese Austenitic intsimbi engenasici.

Ukuhlolwa kwe-Ultrasonic kunye nokuhlolwa kwe-MPI kwenziwa kwi-forging nganye ngaphezu kobude bayo obupheleleyo kunye necandelo, emva komatshini ongqongqo ngokungqinelana ne-API Spec 71. Izatifikethi zovavanyo lwe-Mill ezibandakanya iimpawu zomatshini, uhlalutyo lweekhemikhali, iipropati zemagneti kunye nokuhlolwa zibonelelwa nazo zonke iziqinisekiso.

Sinamandla okuvelisa iNon Magnetic Stabilizer ukuya kuthi ga kwiCrown OD 26''

Ukucaciswa kweMveliso

| Tensile strength | Unikeze Amandla | Ukuqina | IMagnetic Permeability | |

| imiz. | imiz. | imiz. | MAX | I-avareji |

| 120KSI | 100KSI | 285HB | 1.01 | 1005 |

NONE

I-Non Magnetic MWD Sub yenziwe ngeChromium Manganese Austenitic steel stainless, umbhobho ocinezelayo wokuxhathisa uxinzelelo wenziwe ngezinto ezingezizo zokufakela impulser ye-MWD ngaphakathi naphakathi kwezinye. Inkqutyana ye-MWD engeyiyo iMagnetic isetyenziswe ngokubanzi ziinkampani zasekhaya nezamazwe ngamazwe ezombayo.

Lonke uxhulumaniso lwenziwa ngoomatshini ngokwe-API Spec.7-2 kunye neengcambu zentambo zisebenza ngokubanda kwaye zigqunywe nge-API yentambo yentambo kwaye ixhotyiswe ngabakhuseli.

Ukucaciswa kweMveliso

| Ububanzi (mm) | Ububanzi bangaphakathi (mm) | Ubude bombhobho wangaphakathi (mm) | Isiphelo esisezantsi indawo yokuvula (mm) | Umlenze opheleleyo (mm) |

| 121 | 88.2 | 1590 | 65 | 2500 |

| 172 | 111.5 | 1316 | 83 | 2073 |

| 175 | 127.4 | 1280 | 76 | 1690 |

| 203 | 127 | 1406 | 83 | 2048 |

LANDRILL Non Magnetic Materials umgangatho

Iinkcazelo ngeempawu ezingezoMazinethi:

I-Relative Permeability: Max 1.005

Indawo eshushu / Udidi lweNdawo: MAX ±0.05μT

Unyango olulodwa kwi-ID: Roller Burnishing

Emva kokutshisa i-roller, i-compressive layer iyenzeka, izibonelelo ngolu hlobo lulandelayo:

Yandisa iipropathi zokuxhathisa umhlwa, Yandisa ubulukhuni bomphezulu wokubhoboza ukuya kuthi ga kwi-HB400, Yandisa ukugqitywa komphezulu we-bore ukuya kwi-Ra≤3.2 μm, Uvavanyo kunye noHlolo olwenziwe kwibar nganye ngexesha lemveliso ye-NMDC, i-Stabilizer kunye ne-MWD.

Ukubunjwa kweMichiza, uVavanyo lweMpembelelo, uVavanyo loBulukhuni, uvavanyo lweMetallographic (ubungakanani beGrain), uvavanyo lokuTyakala (Ngokutsho kwe-ASTM A 262 Practice E), Uvavanyo lwe-Ultrasonic kubo bonke ubude bebha (Ngokutsho kwe-ASTM A 388), iRelative magenetic Uvavanyo lokungena, uVavanyo lwendawo eshushu, uHlolo lweDimensional, njl.

Iinketho zonyango olukhethekileyo lomphezulu: Ukuchama kwehamile, ukutshisa kwerola, ukuchama kwadutyulwa.

Igumbi 703 Isakhiwo B, iziko Greenland, Hi-tech uphuhliso zone Xi'an, China

Igumbi 703 Isakhiwo B, iziko Greenland, Hi-tech uphuhliso zone Xi'an, China 86-13609153141

86-13609153141