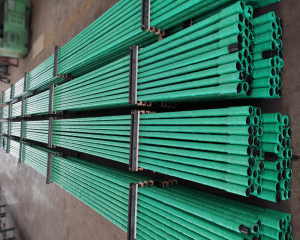

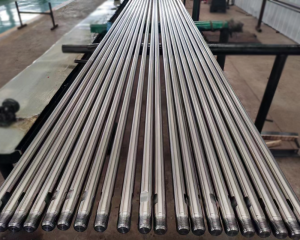

Iimveliso

intonga yesiPolish

Ukucaciswa kweMveliso

I-1.Intonga yasePoland luhlobo oluthile lwentonga ye-sucker edibeneyo kunye ne-sucker rod kunye ne-hanger ye-beam. Iphezulu kwintonga yokufunxa, kufuneka ithwale awona mandla awona mandla, ngoko ke inedayamitha enkulu kunye nenqanaba eliphezulu lentsimbi kunentonga yokufunxa, kwaye umphezulu ugudile kakhulu.

2.Umsebenzi ongundoqo:

Idityaniswe nokupakisha iseti kwibhokisi yokupakisha ukutywina kakuhle kunye nokuthintela ioyile, igesi, ukuvezwa kwamanzi.

Isinxibelelanisi sethutyana phakathi kwentonga yokufunxa kunye ne-hanger yentloko imeyile

Ukugqiba uvavanyo lwesalathisi.

Gqibezela imisebenzi eyahlukeneyo yentloko yemithombo, njengokubetha impompo, ukulawula ukusetwa kwempompo.

Chwetheza itheyibhile yenkcazo

| Ixabiso legama | Intonga yomzimba D | Ubude Lmm士 50mm (Lft 士 2in) | Umsonto wedayamitha yegama mm (ngaphakathi) | mm (in) Igxalaba lomsonto wedayamitha yangaphandle | Ubungakanani bentonga yokufunxa efanelekileyo mm (ngaphakathi) |

| 29 | 28. 6 (11/8) | 2438, 3353, 4877, 6707, 7315, 7925 | 24 (15/16) PR | 一 | 16 (5/8) |

| 27 (1 1/16) PR | 一 | 19 (3/4) | |||

| 29 | 28. 6 (11/8) intonga-upset kwelinye icala | 2438, 3353, 4877, 6707, 7315, 7925 (8. 11, 16. 22, 24, 26) | 24 (15/16 ) SR | 31.8+0.127-0.254 (1.250+0.005-0.010) | 16 (5/8) |

| 27 (1 1/16 ) SR | 38.1+0.127-0.254 (1.500+0.005-0.010) | 19 (3/4) | |||

| 32 | 31.8(1 1/4) | 3353, 4877, 6707,7315, 7925, 9144, 10973 | 30 (1 3/16 ) PR | 一 | 22(7/8) |

| 32 | 31.8 (1 1/4) intonga-upset kwelinye icala | 3353, 4877, 6707,7315, 7925, 9144, 10973 | 30 (1 3/16 ) SR | 41.3+0.127-0.254 (1.625+0.005-0.010) | 22(7/8) |

| 38 | 38. 1 (1 1/2) | 4877, 6707,7315, 7925. 9144. 10973 | 35 (1 3/8) PR | 一 | 25(1) |

| 38 | 38. 1 (1 1/2) intonga-upset kwelinye icala | 4877, 6707,7315, 7925. 9144. 10973 | 40 (1 9/16) SR | 57.2+0.381-0.381 (2.250+0.015-0.015) | 29(1 1/8) |

● IPropati yoomatshini YENsimbi epholishiweyo Rod

| UHLELO | Ubuncinci boBume beSivuno (0.2% iResidual Deformation) | Ubuncinci bokuqina kokuqina | Ubuninzi bokuqina kwamandla | Elongation200mm% | Ukuncipha kwendawo Z% | HRC | HB | Ukudinwa Ubomi | |||

|

| psi | MPa | psi | MPa | psi | MPa | ≥13 | ≥50 | / | / | ≥1.0X106 |

| C | 60000 | 414 | 90000 | 621 | 115000 | 793 | ≥13 | ≥50 | / | / | / |

| D | 85000 | 586 | 115000 | 793 | 140000 | 965 | ≥13 | ≥50 | / | / | / |

| KD | 85000 | 590 | 115000 | 795 | 140000 | 965 | ≥13 | ≥50 | / | / | / |

| H | 115000 | 795 | 140000 | 965 | 173339 | 1195 | ≥13 | ≥45 | / | / | / |

| EHL | / | / | 188500 | 1300 | 217500 | 1500 | / | / | ≥50 | ≥320 | ≥2.5X106 |

| Qaphela: Xa ubuncinci amandla esivuno engenakulinganiswa, kufuneka kuthathelwe ingqalelo ukuba kusetyenzwe kwisampulu eqhelekileyo kunye nokufakela i-extensometer ukulinganisa. | |||||||||||

| A Ngokuqhelekileyo yenziwe ngentsimbi yekhabhoni ephezulu, enokufikelela kwiipropati zomatshini zetafile | |||||||||||

● Ukuma kweMichiza YENXA YEZIXEKO EZIQHELEKILEYO

| AISI | C | Si | Mn | P | S | Cr | Ni | Mo | V | Cu | Al |

| 4130 | 0.26-0.33 | 0.17-0.37 | 0.4-0.7 | ≤0.025 | ≤0.025 | 0.8-1.1 | ≤0.3 | 0.15-0.25 | / | ≤0.2 | / |

| 4140 | 0.38-0.45 | 0.17-0.37 | 0.5-0.8 | ≤0.025 | ≤0.025 | 0.9-1.2 | ≤0.3 | 0.15-0.25 | 0.04-0.09 | ≤0.2 | / |

| 4142 | 0.38-0.45 | 0.17-0.37 | 0.5-0.8 | ≤0.025 | ≤0.025 | 0.9-1.2 | ≤0.3 | 0.15-0.25 | 0.04-0.09 | ≤0.2 | / |

| 4330 | 0.3-0.35 | 0.15-0.35 | 0.8-1.1 | ≤0.025 | ≤0.025 | 0.8-1.1 | 1.65-2.0 | 0.2-0.3 | 0.05-0.10 | ≤0.2 | / |

| 4720 | 0.19-0.23 | 0.15-0.35 | 0.85-1.05 | ≤0.025 | ≤0.025 | 0.8-1.05 | 0.9-1.2 | 0.22-0.30 | 0.02-0.05 | 0.40-0.60 |

/ |

Igumbi 703 Isakhiwo B, iziko Greenland, Hi-tech uphuhliso zone Xi'an, China

Igumbi 703 Isakhiwo B, iziko Greenland, Hi-tech uphuhliso zone Xi'an, China 86-13609153141

86-13609153141