Iimveliso

API 7-1 Casing Section isixhobo sokugaya

Iprofayile yemveliso

I-Mill yecandelo luhlobo lwesixhobo sokuvula i-casing window esidibanisa ukusika kunye nemisebenzi yokugaya. Indawo yokusila ibaleka ingene kwi-casing kunye ne-BHA, kwaye inqumle i-casing kwindawo echongiweyo kuqala. Emva kokuba i-casing inqunyulwe ngokupheleleyo, iya kucolwa ngokuthe ngqo kule ndawo. Emva kokufikelela kubunzulu obuthile, umsebenzi wokuvula ifestile ye-casing ugqityiwe. icandelo lokusila lineenzuzo zesakhiwo esilula, ukusebenza ngokufanelekileyo ukwenza isixhobo esisebenzayo sokuvula ifestile yecasing.

Okwangoku, i-mill yecandelo inokucudisa kwaye ifake i-samente ekusebenzeni kokulahlwa kakuhle, okunokwenza i-samente idibanise ngokuthe ngqo kunye nokwakheka kumgama omde ngaphakathi kwe-360 degrees. I-samente inokungena kwi-reservoir ngokwe-porosity ekhoyo kunye nokuqhekeka kokubunjwa, kwaye umphumo wokufaka iplagi ungcono kakhulu kunokokucudisa isamente emva kokubhoboza.

Umgaqo wokusebenza

Emva kokuba i-mill yecandelo ithotywe kwindawo echongiweyo kwi-casing kunye ne-BHA, qalisa itafile ejikelezayo, uvule impompo, ipiston kwisixhobo ityhalelwe phantsi ngoxinzelelo, i-cone ephantsi yepiston ityhala iiblades zokusika zivule kwaye zilungise. umngxuma ovulekileyo. Xa iileyibhile zokusika zivulekele kububanzi obukhulu, ukulungiswa komngxuma ovulekileyo kugqityiwe. Ngaphantsi koxinzelelo lwempompo eqhubekayo, i-blade inokuvulwa kwaye iphinde ibuyele umgodi ngokuthe ngqo. Emva kokuba ipompo imisiwe, i-piston iphinda isetyenziswe phantsi kwesenzo sentwasahlobo kwaye ii-blades zokusika ziya kuhoxiswa ngokuzenzekelayo.

Iimpawu zemveliso

(1) Uyilo lomatshini, isakhiwo esilula kunye nokusebenza okulula

(2) Uxinzelelo lokuqalisa oluphantsi kunye namandla amakhulu okuxhasa i-blade luncedo kwi-casing cutting;

(3) Uyilo oluphezulu lwentwasahlobo lunceda ukuhoxisa ngokuzenzekelayo umsiki emva kokusika;

(4) Uyilo lwebhloko yokumisa kunye nephini luluncedo ukunyanzela ukurhoxiswa kwesixhobo;

(5) I-blade inokwandiswa okukhulu kwaye ingafakwa kwi-casing efanayo kunye nobukhulu bodonga olwahlukileyo;

(6) I-blade yenziwe ngekhwalithi ephezulu ye-tungsten carbide kunye ne-Bake hughes inkqubo ye-welding efanayo, kunye nokusebenza kakuhle kokusika kunye nobomi benkonzo ende.

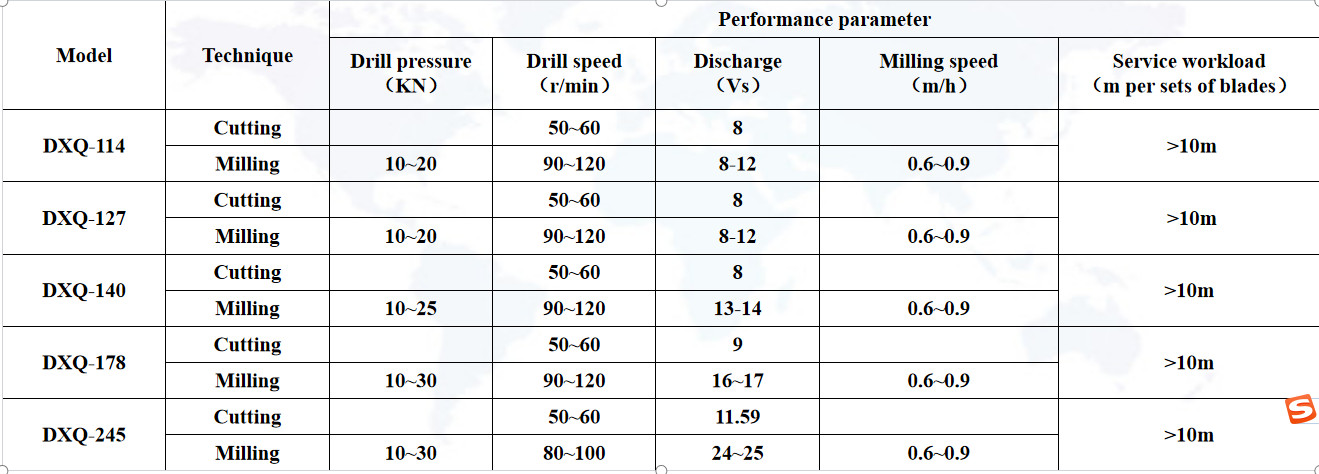

Icandelo lokusila-Ubungakanani betafile

Izixhobo ezihambelanayo - I-taper mill yeklasi ephezulu

Izixhobo zokugaya zonke zenziwe ngomgangatho ophezulu we-tungsten carbide alloy kunye ne-Baker Hughes iteknoloji yokuwelda efanayo. Injongo yolu luhlu lwee-mills kukubuyisela ngokupheleleyo ukukhethwa kwezinto eziphathekayo, ukuyila kwesakhiwo kunye nenkqubo ye-welding ye-Baker Hughes, ukuze kufezekiswe umgangatho ofanayo wemveliso ye-Baker Hughes.

2.Iprofayile yempompo yempompo yeklasi ephezulu

inokuvelisa ilitye lokusila lodidi oluphezulu olunobubanzi obungaphandle obuyi-76 mm ukuya kuma-445 mm. Intsimbi ye-alloy ephezulu isetyenziswe njengomzimba oyintloko, ovumela ukuqhutyelwa kwemingxuma yamanzi amakhulu ukuze kuqinisekiswe ukukhutshwa kakuhle kwenkunkuma yokugaya. Ngelo xesha, ngokweemfuno ezithile zabathengi, isakhiwo semveliso sinokuyilwa ukufezekisa ukusebenza kakuhle kokusetyenziswa.

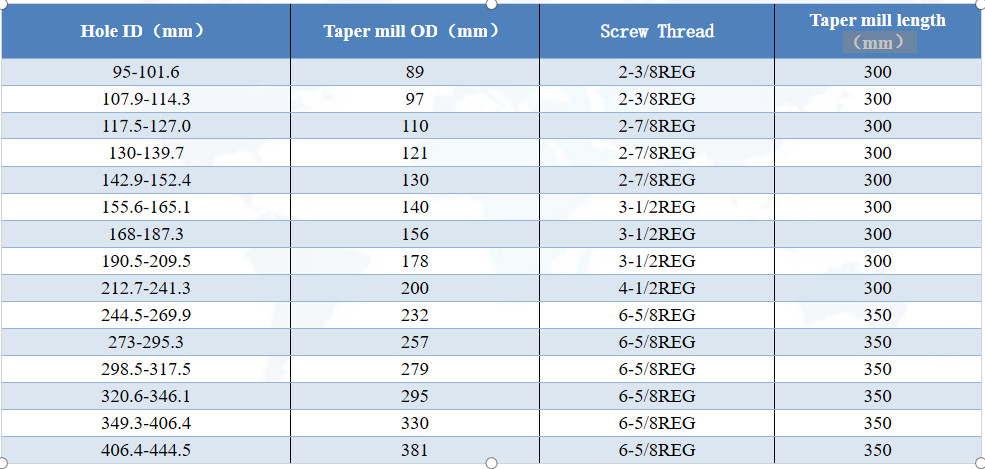

3.Taper yokusila-Ubungakanani itheyibhile

Ubume bemveliso

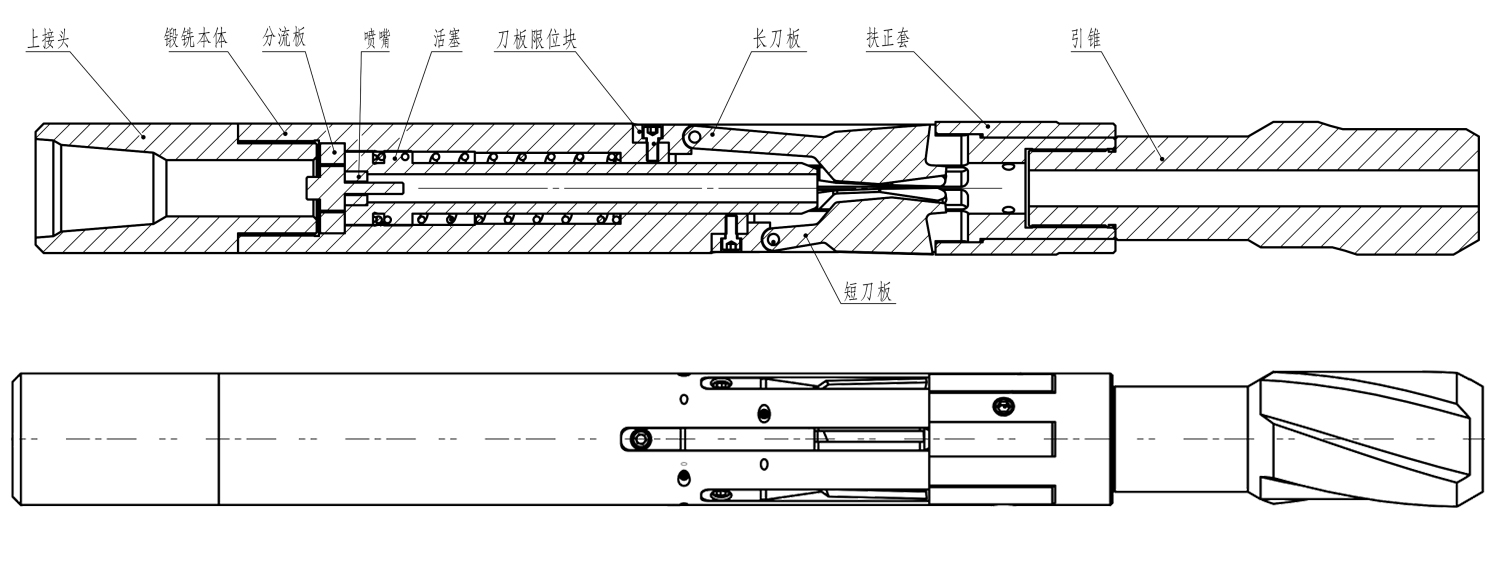

1. I-mill yecandelo ibandakanya ikakhulu ezi nxalenye zilandelayo: ukudibanisa okuphezulu, umzimba oyintloko, i-piston, i-nozzle, ii-blades zokusika kunye ne-cone yesikhokelo, njl.

III.Iinzuzo zobuchwephesha zePetrozhr icandelo lokusila

1.Iveliswe nge-tungsten carbide ephezulu

Iiblades zecandelo lokusila eziveliswe yinkampani yethu zinezi nzuzo zilandelayo:

(1) Imisebenzi yokugaya kunye nokusika ikhawuleza kuneencakuba eziqhelekileyo;

(2) Ukunciphisa uxinzelelo lokugaya olufunekayo ukusika;

(3) Amanqaku amazinyo alungelelene kwaye akukho nqanaba liphumayo;

(4) Ubutyobo obuveliswayo bufana ngakumbi;

(5) Ukuqina kwezinto eziluhlaza kuphezulu kwaye isakhiwo sifanelekile. Xa usebenza, kukusika isinyithi endaweni yokusila isinyithi.

2.Uhlolo olungqongqo lwemathiriyeli ekrwada

I-tungsten carbide ekhethwe yinkampani yethu iya kuthunyelwa kwi-arhente yovavanyo lweengcali ukuze ihlolwe emva kokuba ibhetshi nganye ifike.Ukuqinisekisa ukuba ubunzima be-alloy kunye nezinye izikhombisi zihlangabezana neemfuno zemveliso yenkampani.

3.Inkqubo yewelding egqibeleleyo

Siqasha owayesakuba nguBaker Hughes welding ephezulu kwaye sikhetha izixhobo zokuwelda ezifanayo kunye nezixhobo ezincedisayo kwiworkshop ye-Baker Hughes ukuze siqonde ukuveliswa kobugcisa be-Becker bokuwelda kwinkqubo kunye nezixhobo.

Ukuze kuncitshiswe ukuguqulwa kwezixhobo ngenxa yokutshintsha kwe-thermal ngaphambi nangemva kwe-welding, siseka inkqubo yokufakelwa kwe-welding ukuqinisekisa ukuzinza kwejometri yemveliso kunye nokusebenza kakuhle.

IV.Inkqubo yokusebenza yokugaya iCandelo

Ukulungiswa komngxuma:

1. Lungisa i-casing. Lungisa i-downhole casing nge-taper mill okanye i-casing shaper.

2. Ukucocwa kakuhle. Hlamba i-oyile ekrwada okanye olunye ulwelo equleni ngamanzi acocekileyo.

3. Ukukhuhla i-casing okanye iqula. Ukukhuhla kombhobho kunye nokukhukuliseka kuya kuqhutywa nge-scraper eqhelekileyo kunye nedayamitha yokukhukuliseka ukuya kwi-20 yeemitha ngaphantsi kwendawo yokusila.

4. Lungisa ulwelo lokusila. Iipropati zayo ezahlukeneyo zinokuqinisekisa ukuthwala okuzinzile kwi-debris yentsimbi.

Uvavanyo olusezantsi:

1. Vavanya ukuthembeka kwezixhobo;

2. Ukutshintshwa koxinzelelo lwempompo kuvavanywa xa ii-blades zokusika zivulwa, ezibonelela ngesiseko sokugweba ukuba i-downhole casing inqunywe ngokupheleleyo.

Ukukhetha indawo yokugaya:

1. I-samente ngaphandle kwendawo yokugaya icandelo kufuneka ifakwe kakuhle.

2. Gwema indawo apho i-casing ine-dislocation kunye ne-deformation. Ukuba kukho isikhundla esinjalo, umsebenzi kufuneka uqhutywe kwi-30-40m ngaphezu kwendawo.Kwaye indawo yokuqala yokusebenza yokusika iya kuba yi-1-3m ngaphezu kokudibanisa okukufutshane.

3. Ipokotho kufuneka igcinwe phantsi kwe-shaft. Ngokuqhelekileyo, ubude bepokotho kufuneka bube bukhulu kune-100m.

Ukusika ibhokisi:

① Emva kokudibanisa isixhobo kwi-BHA kunye nokubaleka ukuya kwindawo yokusila yecandelo, qalisa itafile ejikelezayo ukumisela indawo yokudibanisa i-casing ngokwerekhodi (yokugawulwa kwemithi), kwaye uhlise isixhobo ukuya malunga ne-1-3m ngaphezulu kweyona ndawo ikufutshane kunye nebhuleki. .

② Qala itafile ejikelezayo kuqala, ukwandisa isantya esijikelezayo ukuya kwi-50-60r / min, qalisa ipompo, ngokukhawuleza ukwandisa ukufuduka, ukwenzela ukuba uxinzelelo lwempompo lunyuke. Ngeli xesha, uxinzelelo lwempompo lukhula ukusuka kwincinci ukuya enkulu, lukhula ngokuthe ngcembe ukuya kwi-10-12mpa.

③ Qhubeka ukusika i-casing ye-20-45min. Xa uxinzelelo lwempompo lwehla ngokukhawuleza nge-2-5mpa, i-casing iyanqunyulwa. Ukuze wenze umzimba we-cutter uvule ngokupheleleyo, gcina indawo yokusika kule ndawo ye-30min emva kokusika, kwaye ngokuthe ngcembe wandise ukufuduka ukuze uqinisekise ukwakheka okupheleleyo kokuphuka.

Ingxowa yokugaya:

I-WOB inokunyuswa kancinci kancinci emva kokuba i-casing inqunyulwe. elawulwa phakathi kwe-10-25kn, isantya se-rotary sonyuswa ukuya kwi-80-120r / min, kwaye uxinzelelo lwempompo lulawulwa ngaphakathi kwe-10MPa ukuqinisekisa ukuba ukufuduka okujikelezayo kunokuthwala i-debris yensimbi. Xa icandelo ngalinye limalunga ne-0.5m, linokugrunjwa i-1m enye yokuphinda iphinde ijikelezwe, ukwenzela ukuba kube lula i-debris yentsimbi egayiweyo ukusuka kwicandelo ukuze ibuyele kakuhle kwi-annulus. Emva kwemijikelo ye-1-2 yomjikelo, phinda uphinde uqhubeke nokubumba kunye nokugaya.

[Kwinkqubo, kuyimfuneko ukulungelelanisa ngokufanelekileyo ukusebenza kodaka ngelixa ukwandisa ukufuduka; Kwangaxeshanye, hambisa ngokufanelekileyo isixhobo sokomba kwaye ulungelelanise ukujikeleza ukwenza iitshiphu zentsimbi zibuyele ngokupheleleyo kwaye zithintele ukuqokeleleka kobutyobo]

Igumbi 703 Isakhiwo B, iziko Greenland, Hi-tech uphuhliso zone Xi'an, China

Igumbi 703 Isakhiwo B, iziko Greenland, Hi-tech uphuhliso zone Xi'an, China 86-13609153141

86-13609153141